Quality Assurance

Committed To Provide Defect Free Products

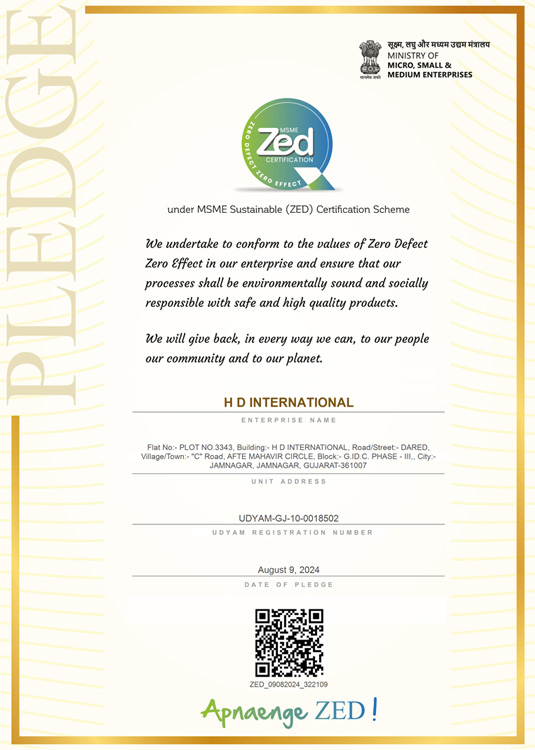

Quality Assurance is an integral part of HD International. We ensure that we are able to deliver high quality products to our customers according to their need. All our valued customers have awarded us consistently ensuring the high quality of our products.

All our products pass through stringent quality testing procedures and inspections. We have an efficient quality control system in place. Quality control begins by checking raw materials for compliance with specifications.

All products are inspected at all stages of manufacturing for defect free surface quality. Our plant has maintained ISO 9001 : 2008, a certification of quality management systems maintained by the International Organization of Standardization and administered by certification and accreditation bodies

Why Choose Us

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time." We have an efficient quality control system in place. Quality control begins by checking raw materials for compliance with specifications.

Instruments

As the Instruments are the heartbeats of industry, to assure good quality, Instruments are required. Company has invested a good amount behind this to have majority type of Inspection instruments including all instruments and gauges along with the profile projector and other sensitive instruments.

Inspection

Company has unique Inspection facility to achieve the goal to zero defects and rejection of any products manufactured. Well experienced and regularly trained technocrat engineers, carry out the Inspection on each Individual product. Batch Inspection is not permitted in the company.

Packing & Dispatch

We understand that packaging is the most important aspect. After Inspection, each order is directed to packing location. The completeness of whole order is checked here. After that packing list gets printed to be included into the packing and the whole order is packed and dispatched.